Paul Fritts Organ Builders

Parkland, WA

Case Maker

March 2015 - March 2021

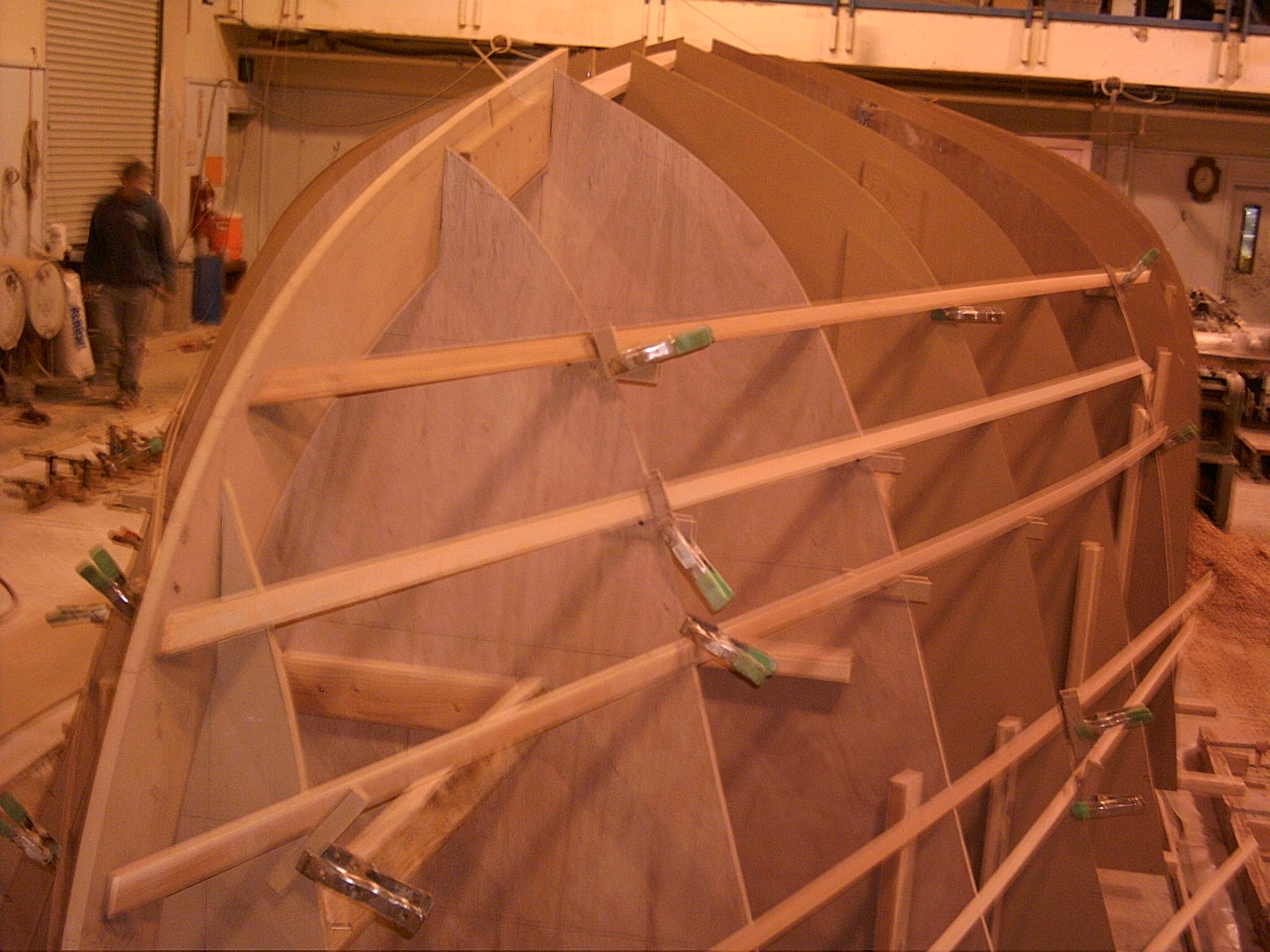

Paul Fritts & Co Organ Builders is dedicated to the design and construction of high-quality pipe organs. All design work and construction of the thousands of components that make up an organ (except for the electric blowers and electronic pre-set systems) is done in-house from carefully selected raw materials.

For six years I had the great pleasure of building wooden cases and pipes for a rare, beautiful, and enduring kind of project — the wooden pipe organ. These instruments are some of the finest being made in the world today, with thousands of parts, sometimes looming several stories above the ground. Photos below show some of the work in progress, and you can learn much more about the process through the documentation of the Murdy Organ build for the University of Notre Dame.

The Center for Wooden Boats

Seattle, WA

Lead Boatbuilder

April 2011 - October 2014

The Center for Wooden Boats is a once-hidden gem on the shores of South Lake Union. Part boat museum, part community center - it is a place where people of all ages and abilities come together to enjoy the water, learn new skills and absorb a little bit of our region's rich maritime heritage.

I spent nearly four years at CWB as Lead Boatwright, during which time I worked on nearly every single one of 52 boats, 35'-10' in size, including seven Blanchard Junior Knockabouts, a hundred year old sailing Gillnetter, and countless rowboats of varying types and origins. These projects not only ensured a working fleet, but they also provided thousands of hours of hands-on learning for the rotating crew of over 100 volunteers and apprentices I supervised in the shop. My role at CWB encompassed boatbuilding and repair, naturally. But it also entailed a great deal of teaching, community engagement, and not surprisingly, tool repair and shop maintenance.

Chesapeake Bay Maritime Museum

St. Michaels, MD

Shipwright Apprentice

October 2010 - March 2011

The Chesapeake Bay Maritime Museum is a non-profit organization dedicated to telling the stories of the Chesapeake Bay and the people who have shaped their lives around it. The Museum’s working boatyard highlights restoration of the Bay’s traditional vessels.

As a Shipwright Apprentice I worked alongside Master Shipwrights to restore the museum's historic fleet. During my time at CBMM I worked on the restoration of the historic vessel Edna E. Lockwood, a 54’ oyster schooner built in 1889. Edna is the last remaining log built bugeye, a type of boat used since the mid 1800's to dredge oysters in Chesapeake Bay.

Schooner Creek Boatworks

Portland, OR

Boatbuilder

March 2009 - March 2010

Schooner Creek Boat Works is the Pacific Northwest’s premier full service boat yard facility.

I worked on a three person crew building the 42' cold-molded Motor Sailor Enchantress. Tasks included lofting, setting up molds, strip planking, applying four layers of cold-molded planking, fiberglass reinforcement, body work, painting, varnishing, and construction of backbone, bulk heads, cabin, cockpit, and windows.

De Bootbouw School

Uitgeest, NL

Boatbuilding Apprentice

October 2006 - March 2007

De Bootbouw School is located in the picturesque Dutch countryside. It is a destination for people of all ages to learn traditional boatbuilding techniques.

During my time at De Booutbouw School I constructed a 17th century Dutch fishing boat for a museum in Zandaam. Tasks included setting up molds, construction of backbone, planking, frames, thwarts, spars and sails. Prepared molds and templates for the construction of the Newfoundland Trap Skiff, which was built by students in a course.

Northwest School of Wooden Boatbuilding

Port Hadlock, WA

Class of 2007

Traditional Large Craft

One of the best boatbuilding schools in the world, The Northwest School of Wooden Boatbuilding provides an education in craftsmanship, first and foremost.

As a student of the Traditional Large Craft program, I learned my trade while building a 32' motor sailor from the ground up and a Hereschoff 12.5’. The boat school provides the foundation needed for a lifetime of craftsmanship in the woodworking trades.